IntelliLogger™ IL-Mini

A Rugged, Low-Power, Stand-Alone Data Logging and Alarming Instrument

| IL-Mini Key Features | |

|---|---|

| Rugged weatherproof package | |

| Directly connect thermocouple, mAdc and Vdc inputs (multiple ranges) | |

| Low-Power for battery, photovoltaic or grid power | |

| Unlimited programmability via powerful HyperWare-II icon-based software. | |

| Internal battery and transducer excitation options | |

| LCD Display option for status and real-time data display | |

| Internal memory for up to 160,000 readings | |

| Optional CF Card socket for removable 10 million+ reading storage | |

| 4-20mA and Vdc transducer excitation from internal batteries (PSM-4) |

Derived from the powerful industry proven IntelliLogger™ Network Enabled data acquisition, alarming and reporting instrument line, the IntelliLogger IL-Mini™ family offers much of the same capability (excludes Network capability)… for a budget sensitive price. The IL-Mini is offered two main models… one in a deeper enclosure that includes an internal battery pack for total portability and another model in a shallow enclosure designed to accept external power.

Boldly differentiating itself from competitive low-cost data loggers, the IL-Mini™ is extremely flexible and unique due to its programmability with the industry proven HyperWare-II icon-based programming software.

With its low-power operation and rugged weatherproof packaging, the IL-Mini™ serves equally well as a portable data logger or as a long term monitoring logger. The IL-Mini™ is perfectly suited for energy audits, R&D test applications, compressed air audits, Measurement and Verification studies and unlimited other lab and field data collection applications!

Product Images

Product Information

Overview

The IntelliLogger IL-Mini™ is an extremely versatile stand-alone data logging and alarming instrument… offered at a very cost competitive price point. The IntelliLogger IL-Mini™ is programmed via Logic Beach’s industry proven icon-based HyperWare-II software… the same powerful software used with the network enabled IntelliLogger™ product family. Compatibility with HyperWare-II results in a level of data logging and alarming flexibility never before available in such a low-cost instrument.

Packaged in a gasketed door, rugged weatherproof enclosure, the IL-Mini™ data logger is ready to deploy in a plant, at a remote site or on a vehicle for R&D data logging, energy audits, compressed air audits, emissions monitoring, flow characterization or a multitude of other data collection and alarming tasks. The IL-Mini is offered two main models.. one in a deeper enclosure that includes an internal battery pack (and optionally the PSM-4 transducer excitation power supply) for total portability and another model in a shallow enclosure designed to accept external power.

The IntelliLogger IL-Mini™ is offered with a full suite of options to meet your specific data collection and alarming needs.

All models of the IntelliLogger IL-Mini utilize the powerful and intuitive HyperWare-II software for programming. HyperWare-II facilitates a quick learning curve due to its graphic programming User Interface. Simply dragging icons onto the workspace then interconnecting the icons with your mouse defines program function. This program is then uploaded to the Intellilogger memory where it executes stand-alone.

Options for the IL-Mini include Modbus data collection, analog channel variations, expanded memory, internal batteries and sensor excitation.

Specifications

Following are IntelliLogger IL-Mini™ Specifications. The IntelliLogger IL-Mini™ was designed as a rugged data logger for industrial and harsh environment data acquisition and alarming applications. The unit is equally suited for portable data logger applications such as in energy audits, compressed air audits, field test and troubleshooting as well as in permanent long term data logging and alarming applications.

| IntelliLogger™ IL-Mini | |||

|---|---|---|---|

Power |

|||

| Voltage Input Standard | 7 to 28 Vdc with transient protection | ||

| Voltage Input (Wide Range Option) | 9Vdc start, 5Vdc run with 60Vdc continuous withstand. Load dump and transient clamped. | ||

| Power (Full Power Mode with LCD) | ~15mA sleep between readings with ~30mA peaks during readings (~10mS duration, depends on channel configuration) at 12Vdc input. | ||

| Power (Full Power Mode with LCD blanking or uninstalled) | ~3mA sleep between readings with ~30mA peaks during readings (~10mS duration, depends on channel configuration) at 12Vdc input. | ||

| Power Options |

|

||

Environmental |

|||

| Operating Temperature | -40 to 70C (LCD will not function below approximately -20C) | ||

| Enclosure Environmental Rating | NEMA 4x equivalent (non-certified) | ||

.Mechanical |

|||

| Weight: |

|

||

| Dimensions |

|

||

.User Interface |

|||

| Serial Comm (to PC) | USB 1.1 | ||

| Display |

|

||

| LCD Operational modes |

|

||

| Front Panel User Buttons |

|

||

| Panel Indicators |

|

||

| Power Switch | On/Off control (switches power source) | ||

.Analog Inputs; General |

|||

| Analog Sampling Rate Overview | Each input channel can be individually configured for Sampling Rate per Program Net configuration. Maximum sampling rate for input channels depends on configuration of the input channel (eg filtering, settling time, etc) and the complexity of the Program Net implemented. However the following are some baselines for general reference: | ||

| Vdc-Lo, mAdc and thermocouple inputs Sampling Rate | Direct to memory with default settings: 100 S/Sec | ||

| Vdc-Hi Channel Sampling Rate | Direct to memory with default settings:

|

||

| Analog to Digital Conversion Resolution |

|

||

| Channel Quantity | 4 individually configurable channels | ||

| Analog Advanced Settings |

|

||

.Vdc-Lo Analog Inputs (included in all models) |

|||

| Eight user programmable ranges of low level voltage input are provided standard. Each channel can have a unique input range under user control. | |||

| Vdc-Lo Input Ranges |

|

||

| Vdc Reading Accuracy | +/-0.2% of Full Scale (typical +/- 0.1% FS) | ||

.mAdc Analog Inputs (Option) |

|||

| Five user programmable ranges of DC current are provided with the mAdc option. Each channel can have a unique input range under user control. | |||

| mAdc Input Ranges |

|

||

| mAdc Reading Accuracy | +/-0.3% of Full Scale (typical +/- 0.1% FS) | ||

.Vdc-Hi Analog Inputs (Option) |

|||

| Three user programmable ranges of Higher level voltage input are provided standard. Each channel can have a unique input range under user control.1 | |||

| Vdc-Hi Input Ranges |

|

||

.Thermocouple Inputs (Option) |

|||

| Supported Thermocouple Types | J, K, E, T, R, S and N types supported with direct terminal strip connection. | ||

| Thermocouple Input Ranges | Full and Limited ranges are provided for most input types allowing for higher resolution readings when wide temperature input range is not required. User selectable DegC or DegF |

||

| Full Range / Limited Range (Deg C): |

|

||

| Thermocouple Accuracy | Aggregate Accuracy (includes CJC error): +/- 1C (+/-0.5C typical over -20 to 60C instrument temperature) | ||

| Cold Junction Compensation | Automatic for Thermocouple measurement CJC Range: -40 to 70C Accuracy:+/-0.5C, (0.2C typical over -20 to +70C) |

||

| CJC Icon (Standard) | An icon is provided for use in the Program Net which reports terminals trip temperature for use in thermocouple reading cold junction compensation. The CJC function is performed automatically if thermocouple inputs are connected. Additionally, the CJC temperature is provided as a user accessible input channel (icon) for utilization in the Program Net and monitoring of unit temperature. |

||

.Digital Input (included in all models) |

|||

| The Digital Input can be configured under user control for Event, High speed counter or Frequency input. | |||

| Event: |

|

||

| Hi-Speed Counter | Accepts square, triangle and sine wave inputs. Baseline operational specs follow:

|

||

| Frequency | Typical Input range: 1 to 30Khz The frequency input channel utilizes specialty amplifiers for maximizing sensitivity to low frequency low amplitude input waveforms. |

||

| Sensitivity at low frequency baselines: |

|

||

.Vsupply Analog Input (Standard) |

|||

| Vsupply Icon | An icon representing the Vinput to the IntelliLogger is available for use in Program Nets. Can be use for monitoring internal battery state of charge, PV charged external batteries, grid power fails, etc with corresponding alarming | ||

.Outputs (1 Digital Output standard) |

|||

| Supplied standard with one digital output. Order options include various combinations of relay and digital outputs. Up to two digital outputs or two relay outputs or one of each can be provided. | |||

| Digital Output | 0/5Vdc outputs through 200ohm protection resistance. Short circuit protected (continuous) | ||

| Relay Output | Form C (normally open, normally closed and Common terminals are provided to user). Contacts are isolated from all internal IntelliLogger IL-Mini™ circuitry. Current Rating: 1A AC/DC2 |

||

.Modbus RTU (Master or Slave Option) |

|||

| Modbus Communications |

|

||

| Modbus RTU Master |

|

||

| Modbus RTU Slave | User defined icons within Program Net allow for sharing of analog values, calculated values, states, etc. | ||

.Logged Data Memory |

|||

| Data Storage Memory (internal) |

|

||

| Memory Card (Option) |

|

||

| Data Logging Modes (Standard) |

|

||

1Note: To preclude personal harm as well as potential instrument damage, at no time should voltages exceeding 32Vdc ever be applied to any terminals on the IntelliLogger IL-Mini™.

2Note: For switching of inductive loads (relay coils, solenoids, etc), it is highly recommended that clamping diodes or other suppression devices be installed across the relay output terminals to protect from inductive kick voltages upon load circuit current interruptions.

3Note: It is highly recommended that the Logic Beach CF-IND-128MB, industrial temperature rated, 0 wait-state, 100% tested Compact Flash card be used with the IntelliLogger product family.

Programming

The IntelliLogger IL-Mini™ utilizes the unique and powerful HyperWare-II software to provide flexibility and intuitive programmability never seen before in a low cost data logging instrument. The historical compromise of flexibility vs cost in low-cost data logging platforms is now history.

Within HyperWare-II, simple drag, drop and mouse interconnection of icons builds a visually intuitive data logging and alarming program that is then uploaded into the IntelliLogger IL-Mini™ where it executes.

Icons representing analog and digital inputs as well as processing (math, min/max, integration, etc) and final output (log memory, alarm outputs) are simply interconnected to build the desired Program Net.

Conditional logging, threshold alarms, inter-channel calculations, flow calculations (time integration), duty-cycle calculations, logic, energy interval totals, time and date scheduling and much more are all quickly programmed and readily handled by the IntelliLogger IL-Mini™.

Based on the user developed program, the IntelliLogger IL-Mini™ samples analog, digital and even Modbus inputs, processes the readings and stores the results to internal memory or a removable CF card… Simultaneously it processes any user programmed alarm strategies and outputs accordingly.

In addition to the programming capability included in HyperWare-II, communications, data downloads and Real-Time trending features are provided. With the Real-Time Trending feature, custom dashboards can be built and saved with readings connected to a multitude of display graphics such as thermometers, line plots, charts, gauges and much more.

Options

To meet specific customer application requirements and still maintain a budget sensitive price, the IntelliLogger IL-Mini™ is offered with a multitude of user selectable options.

All IL-Mini’s™ include the following features:

| Data logging and alarming instrument with full support for programmability from HyperWare-II | |

| Weatherproof, gasketed door enclosure with wiring ports and sealing gland fittings. | |

| 4-line x 20 character liquid crystal display | |

| Four analog inputs supporting 8 Vdc ranges from 20mVdc full scale to 2Vdc full scale. | |

| One General Purpose Digital input (user configurable for Frequency, Hi-Speed Counter or Event) | |

| Integral temperature sensor (also used for cold junction compensation with thermocouple input option) | |

| Two user programmable Green LED indicators | |

| One Digital Alarm output with indicator LED | |

| 50,000 reading internal memory | |

| USB connectivity | |

| On/Off switch | |

| CD containing user manual PDF |

IL-Mini Available Options:

Modbus Options: |

|

| MN-MRM; Modbus RTU Master | |

| MN-MRS; Modbus RTU Slave | |

Input Channel Signal Type/Range Options: |

|

| MN-TC; Direct J, K, E, T, R, S, and N type thermocouple input with integral Cold Junction Compensation | |

| MN-MA; Eight ranges of mAdc current input capability, up to and including 4-20mAdc input. | |

| MN-HV; Three higher Vdc input ranges up to 30Vdc directly. | |

| MN-TCMAHV; Includes all of the above… mA, higher voltage and thermocouple input…on all four channels | |

Power Options: |

|

| MN-HV; Wide range power input for vehicle applications. | |

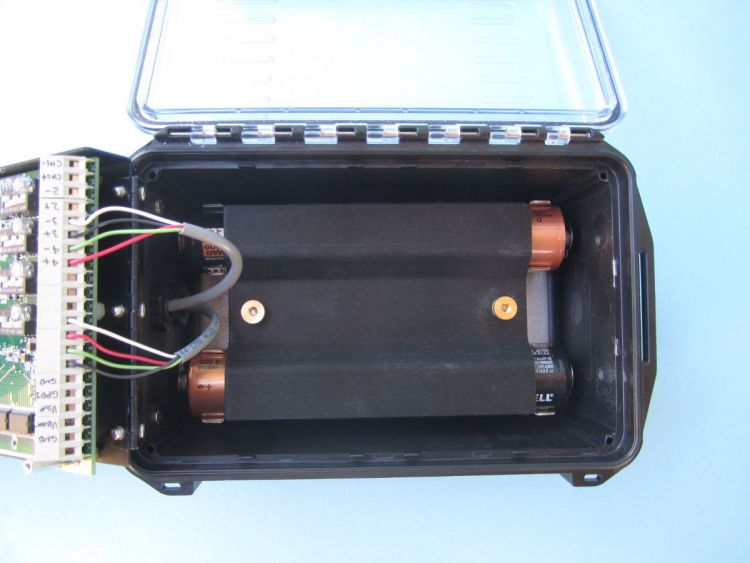

| IL-Mini-Batt; Internal 6 alkaline D-cell battery pack. Deeper enclosure and batteries included. | |

| IL-Mini-Batt/PSM-4; Integrated 24Vdc output 100mA high-efficiency power supply for transducer excitation power from D-Cell batteries or External Power | |

Logged Data Memory Expansion Options: |

|

| MN-EXM; Internal memory expansion to ~160,000 readings | |

| MN-CF; Removable Compact Flash memory card for logging up to approximately 1 million data samples (includes one CF Card) | |

Output Options:The IL-Mini has two outputs. They can be configured as relays, digital outputs or a mix. Contact Logic Beach for non-listed variations. |

|

| MN-2R; Both outputs configured as normally open (NO) relays | |

| MN-2DO; Both outputs configured as Digital outputs | |

Documentation

Frequently Asked Questions

- What is the difference between the IntelliLogger and the IntelliLogger IL-Mini?

- The main difference is that the IL-Mini does not have any of the network capabilities (FTP, Email, Ethernet connection, Cell Modem) of the IntelliLogger instrument.

- Additionally the IL-Mini is limited to 4 analog inputs. Both instruments utilize the powerful programmability offered by HyperWare-II.

- What components do I need to order to make a complete usable IL-Mini data acquisition instrument?

- The IL-Mini Instrument, a HyperWare-II user license, a power source and a Type A to Mini-B USB cable. Refer to the Ordering section for details.

- Does HyperWare-II come with the IL-Mini?

- In an effort to keep the cost of the IL-Mini to a minimum, purchase of a HyperWare-II single user license is required for use with the IL-Mini. A single user can install HyperWare-II on up to 3 PC’s (eg work, laptop and home PC). The HyperWare-II will function for both the IL-Mini and IntelliLogger instruments and will recognize the model when a connection is made.

- How can I get more Input/Output channels?

- The IL-Mini is limited to 4 analog inputs. Options are available to add input signal and thermocouple capability to those 4 channels. Up to 2 relay outputs or 2 digital outputs can be specified at order time.

- Also note that the IL-Mini can connect to Modbus RTU devices expanding the channel count.

- Will the IL-Mini run stand-alone without a PC connected?

- Yes. Once the IL-Mini is programmed, it can run stand-alone sampling inputs, performing calculations, driving outputs, etc. Options include various battery options to implement true stand-alone operation.

- Does the IntelliLogger provide power for sensors?

- The IL-Mini can be provided with a D-cell battery pack and a PSM-4 integral power supply. The PSM-4 can step up the nominal 9Vdc from the batteries to 24Vdc for transmitter (eg 4-20mA) excitation.

Alternatively, the PSM-2 external power supply can be used for integrated systems.

- The IL-Mini can be provided with a D-cell battery pack and a PSM-4 integral power supply. The PSM-4 can step up the nominal 9Vdc from the batteries to 24Vdc for transmitter (eg 4-20mA) excitation.

- I am running the IntelliLogger from batteries.. how can I power transducers?

- Use the PSM-4 or the PSM-2 module (see above) to step up battery voltage to levels sufficient to power most transducers. Additionally, to conserve battery energy in slower sampling applications, the power to the transducers can be cycled on before a reading then off after the reading.. saving battery energy. This is commonly done with the Warm-Up Icon.. a standard feature in the HyperWare software.

- Is the IL-Mini weatherproof?

- Yes, the IL-Mini is housed in a gasketed door weatherproof enclosure that effects a NEMA 4X rating. The unit should not be immersed.

- What can be viewed on the IL-Mini front display?

- Front panel buttons allow users to step through liquid crystal display (LCD) menus to view:

- System Status (Enabled/Stopped, Memory usage, Supply voltage, etc)

- Real-time values associated with any Probe Points included in the Program Net.

- User defined messages displayed per the Program logic

- System Error messages (Memory Full, Low Supply Voltage, etc)

- and more!

- Front panel buttons allow users to step through liquid crystal display (LCD) menus to view:

- Can a cellular modem be used with the IntelliLogger?

- No, Use the IntelliLogger instruments for cellular data modem connection.

- Can the IntelliLogger be connected to a local area network (LAN)?

- No. Use the IntelliLogger instruments for network capabilities.

- Can I prevent unauthorized access to the IntelliLogger?

- Yes. The IL-Mini has a powerful Password authentication system. Multiple User accounts can be built with varying Permissions. For example, an Operator User could be set up to allow for viewing of real-time values but can’t reprogram the unit. A Power User might be able to Perform all functions but NOT reprogram the unit, etc.

- What happens if a power failure occurs?

- The IL-Mini will shut down upon a power failure and save all current readings to non-volatile memory. When the power returns, the IntelliLogger will reboot and resume the operational mode which it was in prior to the power failure.

- Can I use a backup battery to power the IntelliLogger through utility outages?

- Yes, the IL-Mini can be connected to both a low voltage utility source (eg the provided 120Vac to 12Vdc power adapter) and to a the nominal 9Vdc Battery Pack option. If the utility power fails, the IL-Mini will automatically switch to the backup battery and continue operation. When the utility power resumes, the IL-Mini will commence operation from the utility source again. If running from a nominal 12Vdc source battery as backup, use of a 120Vac to 24Vdc adapter will ensure the IL-Mini only draws current from the battery when the utility fails.

Ordering

| IL-Mini | |||

|---|---|---|---|

| Three IL-Mini models are offered: | |||

| Part Number: | Price: | ||

| IntelliLogger IL-Mini Data Logging Instrument | 9080.50060 | $600 | |

| IntelliLogger IL-Mini Data Logging Instrument with integral battery pack and deeper enclosure. | 9080.50062 | $660 | |

| IntelliLogger IL-Mini Data Logging Instrument with integral battery pack, deeper enclosure and PSM-4 Sensor Excitation power supply | 9080.50063 | $760 | |

| | | |||

| Items included with order: | |||

| Component Description: | Part Number: | Qty: | |

| IntelliLogger IL-Mini, includes weatherproof enclosure | 9080.5006x | 1 | |

| Liquid Tight Fitting with Nut | 3522.15003 | 4 | |

| Hole Plug for unused fittings | 3522.95022 | 4 | |

| IntelliLogger IL-Mini Manual | CD | 1 | |

| | | |||

| IL-Mini Instrument Options: | |||

| Option Description: | Order Part Number: | Price: | |

| Eight ranges of current (mA) to all 4 analog input channels (includes 4-20mA range) | MN – MA | $50 | |

| J, K, E, T, R, S, and N type thermocouple input to all 4 analog input channels | MN – TC | $50 | |

| Three higher Vdc ranges for all 4 input channels. | MN – HV | $50 | |

| Input Bundle; includes: MN – TC, MN – MA, and MN – HV inputs to all 4 analog input channels | MN – TCMAHV | $120 | |

| Modbus RTU Master capability | MN – MRM | $280 | |

| Modbus RTU Slave capability | MN – MRS | $220 | |

| Additional Relay Output (System total of 1 Relay and 1 Digital output) | MN – 1DO1R | $25 | |

| Two Relay Outputs (Omits the normally included Digital Output) | MN – 2R | $50 | |

| Additional 0/5Vdc Digital Output (increases system total to 2 Digital outputs) | MN – 2DO | $20 | |

| One Relay and 1 additional 0/5Vdc digital output (System total: 1 Relay and 2 Digital outputs) | MN – 2DO1R | $65 | |

| Compact Flash memory card socket. Includes one industrial temp, 0 wait-state CF card (10m+ reading capacity) | MN – CF | $80 | |

| Expanded Data storage Memory (~160,000 reading internal data memory) | MN – EXM | $40 | |

| Data Storage bundle; MN – EXM and MN – CF options both provided | MN – EXMCF | $110 | |

| Wide range instrument power input (typically used for vehicle powered applications) | MN – WP | $90 | |

Contact Logic Beach directly to purchase this product.

Contact Logic Beach directly via phone or email with questions and/or to place your order.

Our Applications Staff welcomes your inquiry!

Accessories

CF Memory Card

To expand IL-Mini data storage capacity and provide removable memory.

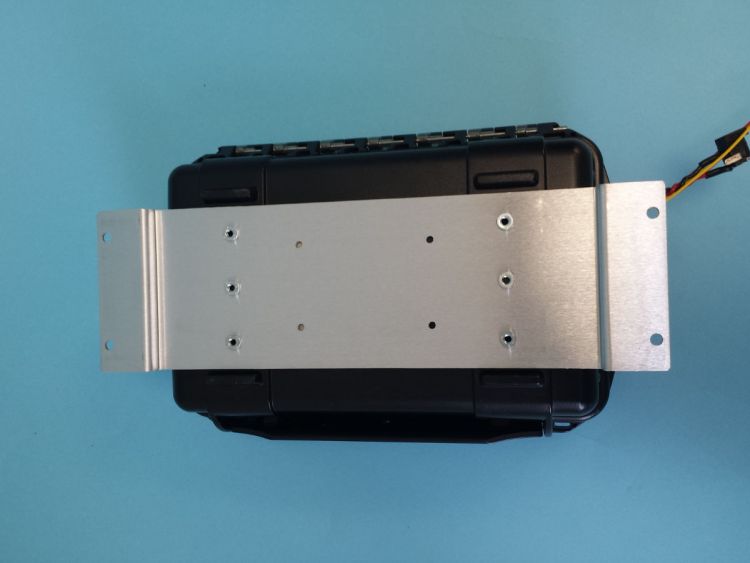

Surface Mounting Bracket

For mounting an IL-Mini to a wall or enclosure back.

120/240Vac 12Vdc Power Supply

Provides 12Vdc power for IntelliLogger operation.

120/240Vac 24Vdc Power Supply

Provides 24Vdc power for IntelliLogger operation.

USB Cable Type-A to Mini-B

6ft Type-A to Mini-B cable for IL-Mini to PC USB port connection.