Intelligent Data Logging using the Delta Icon

Intelligent Pressure Logging Overview

![]()

One of the many powerful capabilities offered by HyperWare-II and the IntelliLogger™ instruments that is invaluable in Compressed Air Audits is the Delta Logging feature. Delta logging allows an analog signal (for example, air pressure) to be sampled by the IntelliLogger™ quickly but the sampled data is only stored to memory if the current value changes by some user defined amount from the last stored value. The benefit of Delta Logging is obvious when logging analog values that are fairly stable most of the time but on occasion experience transient excursions that are of interest.

In many installations, compressed air manifolds very closely resemble this analog profile in that the pressure can be fairly stable for long periods of time but when a large pneumatic load occurs, the pressure droops. Trapping this phenomenon can lead to a better understanding of the dynamics of the demand side of the compressed air system. Once the air pressure profile is known, decisions relative to system modifications can be intelligently made.

The Benefits of Delta Logging

The net benefit of Delta Logging is that an analog signal (eg air pressure) can be profiled as accurately as desired without:

- Storing massive amounts of repetitive, useless data to logger memory… and suffering through the ensuing data download, storage on hard drives, tedious sifting through data for analysis and putting heavy demands on data analysis applications.

- Compromising to a slower sampling rate to minimize the amount of data stored but at the cost of missing transient waveforms (pressure excursions). These missed transients could be invaluable in assessing compressed air system performance as well as troubleshooting.

Delta Logging of Pressure Example

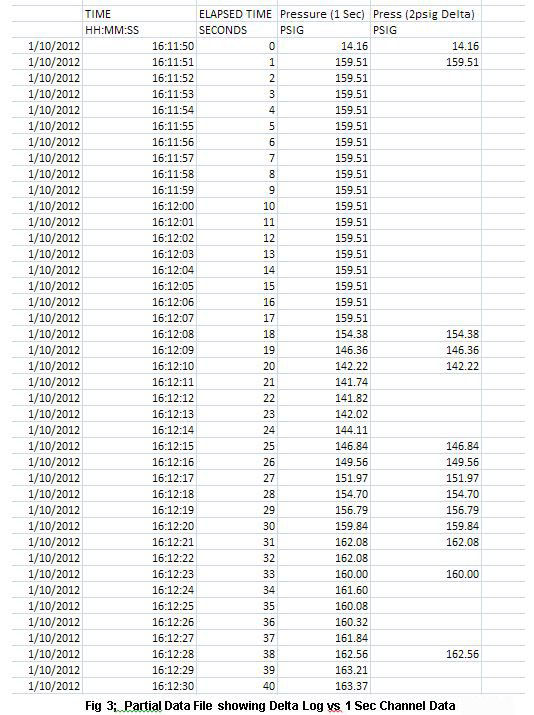

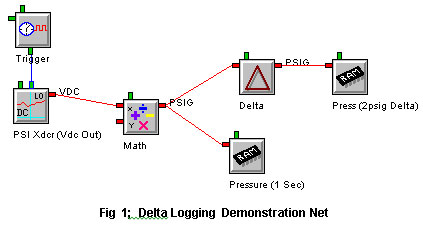

To better understand Delta Logging, take a look at the Program Net shown in Figure 1. In this Program Net, the Sample Rate Clock (named Trigger) forces sampling of an analog voltage from a pressure transducer (icon named PSI Xcdr) every second. The Vdc signal representing pressure is then fed through a Math icon where it is algebraically converted to pressure (psig). For purposes of this test, the pressure signal is then sent to the IL-Mini™ data memory via two paths… one direct (which will be logged every second) and the other via a Delta icon then to memory.

The Delta icon has been set to pass data to Memory if the current value is different from the last stored value by 2 or more psig.

In Fig 2, the two channels are plotted after a short logging session. As the plot shows, the yellow Delta Channel approximates the red 1 second data profile within 2 psig as programmed and expected. The big benefit can be seen in the snippet of the raw data file (Fig 3) where the data logged for the 1 sec pressure channel consumed 72 data points and the Delta channel consumed 25 data points over the same data logging period. The memory savings will vary depending on the dynamics of the signal and the Delta icon setting… however commonly, users recognize savings of 10x to 100x reduction in memory usage by using the Delta icon! This savings relates to considerable savings in cost and time… less data to analyze, less data to store and process, less data to backup, etc.