Environmental Chamber Data Acquisition & Alarming

Application

From commercial, high volume test labs to the occasional in-house Engineering test… rapid environmental chamber monitoring and test system setup and deployment is critical. In many cases, 7/24 monitoring and data acquisition of chamber conditions as well as the Unit Under Test (UUT) parametrics are required. Additionally, in many tests, it is necessary to perform cyclic control of pneumatics, electrical loads, hydraulic pressures, etc to stress the UUT.

IntelliLogger Solution

The IntelliLogger™ network connected data logging and alarming instrument is perfectly suited to Environmental Chamber test monitoring and alarming applications due to its many key integrated features:

- Quick programming with the Intuitive HyperWare-II icon based programming

- LAN connectivity (integral Ethernet port) provides quick and easy access for…

- Instrument programming

- Real-time monitoring (even via browser)

- Alarm and Status email and text message outputs

- Browser access with programmable permissions

- Automatic FTP of data for unattended test data archiving

- Stand-alone operation… no PC required

- Isolated high resolution analog inputs with digital and relay outputs

- IntelliLogger outputs can be used to control stressors applied to UUT (eg cycling pressure, applied voltage, etc)

- Chamber condition monitoring and UUT monitoring

- Integral data logging of test data and conditions

- Small size for location proximate to the Environmental Chamber or Test Station

- Low cost and off-the-shelf availability

Instrumenting the Test

With the IntelliLogger built in network capabilities, field expandable high resolution analog inputs, analog and digital outputs, CF card socket, local display and its full suite of network capabilities, the IntelliLogger readily handles both chamber condition monitoring and the UUT parametric data logging… all in one standalone instrument… with no dedicated PC requirements.

Simple terminal strip connections and fully isolated analog inputs make for quick connection of thermocouples, voltage and current signals from most types of sensors. With the integral isolated inputs, connection to DC levels, 4-20mA loops and other signal levels with differential voltages is simplified… concerns about common mode signal ranges are gone.

Typical Test Sequence – Getting the test going…

Install and wire up the IntelliLogger™ and unit under test (UUT)

Make the necessary test connections between the IntelliLogger data acquisition instrument and the UUT located in the Environmental Chamber… whether they be thermocouple temperature sensors, pressure sensors, flow, radiation, light, voltage, current, etc… the isolated high resolution analog inputs of the IntelliLogger can accept the signals.

Network Connected IntelliLogger wired to sensed parameters on UUT in Environmental Chamber

Many tests may require the application of cycled stress or condition changes. The IntelliLogger analog outputs as well as its integral digital and relay outputs can be simply wired to pneumatic valves, electrical loads, etc to perform cycled stress application during the test.

IntelliLogger controlled pneumatic valve for pressure cycle testing

Program the IntelliLogger™

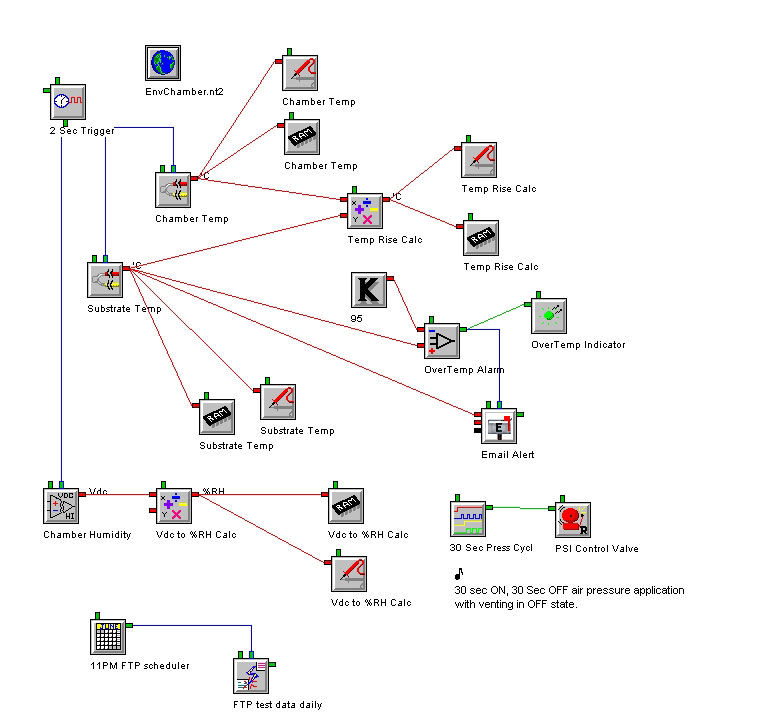

With the provided HyperWare™-II software, configuration of the data acquisition inputs (to internal memory or removable CF card) and output is quick and simple… yet not compromising in flexibility. The icon based programming of HyperWare-II facilitates quick construction of Program Nets which are then loaded into the IntelliLogger’s memory where the program executes… sampling inputs, converting signals to Engineering units, performing statistical analysis, logging data, controlling test conditions and providing local alarming.

Quickly develop the IntelliLogger Program Net on a network PC,

then upload to the IntelliLogger’s memory where it executes.

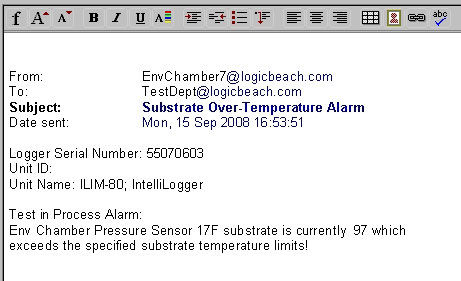

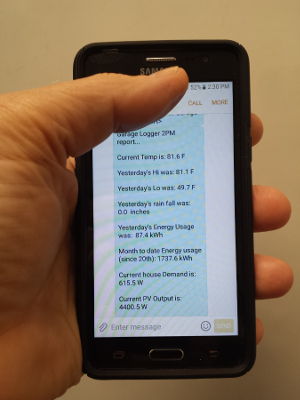

Additionally, with the network features built into every IntelliLogger, in the event of a problem, an email or text message can be sent by the IntelliLogger … with embedded current values! Also, for peace of mind, simple status messages can be sent as well.

As the critical testing proceeds, the IntelliLogger can be programmed to automatically FTP (or email) logged data to an FTP server for archive or feed into further 3rd party processing applications.

Program Net executing in the IntelliLogger

In the Program Net shown, humidity, ambient chamber temperature and UUT substrate temperatures are being monitored and logged. Temperature rise calculations are performed and saved to IntelliLogger memory. If the UUT substrate temperature excceds 95C, an alert email is sent. Additionally, every night at 11pm, an FTP is sent to a network connected FTP server for data archiving and post-processing.

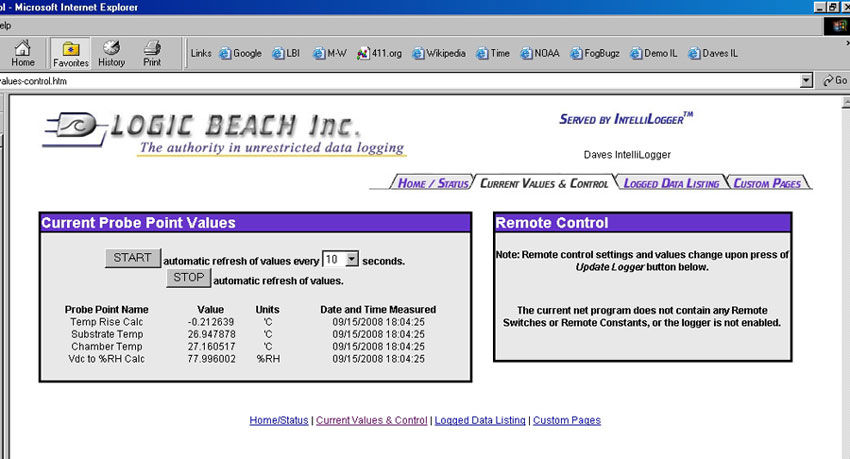

Staff with permission rights can even access the IntelliLogger for real-time readings (and to download data) using their browser… or custom Web pages can be built with graphics, gauges, thermometers, etc and these graphic enriched custom pages can be viewed with the free Logic Beach GreenWater™ browser.

View current readings and control outputs via a browser (with permission rights)

Run the Test

Start the test and allow the IntelliLogger to archive the parametric data, monitor conditions in the chamber and on the UUT, alarm as necessary and report real-time values via browser or HyperWare-II network connection… and optionally FTP’ing data to a server for archive.

Email alert received due to over-temperature of substrate

Generate cell phone Text Messages

as alerts or for test status

Download and Analyze the Test Data

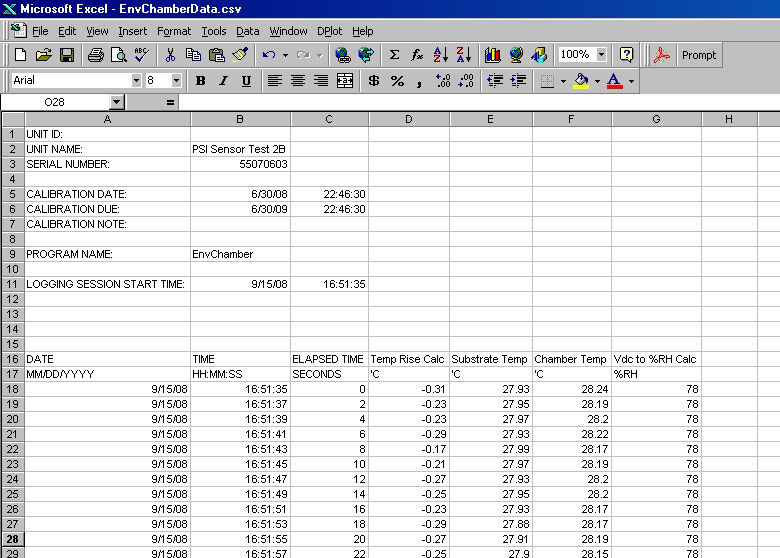

After (and during) the test, download data from the IntelliLogger’s internal or CF card memory. Downloaded data can be converted to Excel readable CSV files or other formats for further analysis by the HyperWare-II integral plotter or 3rd party analysis and plotting applications.

Download and review data as CSV file… readily handled by Excel and other applications