Modbus RTU Master Option for the IL-Mini™

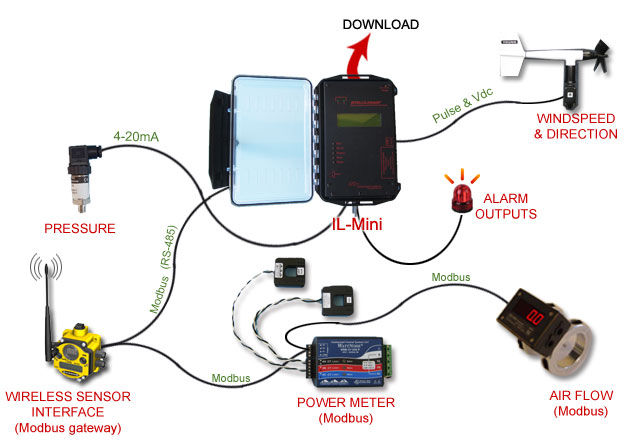

IntelliLogger IL-Mini™ shown with Modbus RTU connected Flow, Power and Wireless Sensor Modbus devices along with directly connected analog Temperature, Pressure and Wind direction and speed transducers

| Modbus Option Benefits | |

|---|---|

| Query connected Modbus ‘smart’ transducers | |

| Expose internal registers to other Modbus devices | |

| Remotely control IntelliLogger outputs | |

| Adjust IntelliLogger operation via Modbus | |

| Acknowledge IntelliLogger programmed alarms | |

| Change IntelliLogger alarm |

Product Information

Overview

IntelliLogger IL-Mini™ Modbus Capability

![]()

IntelliLogger IL-Mini’s™ equipped with the Modbus RTU Master option can read (and optionally write) register values from (to) other Modbus networked Slave devices. 1000’s of Modbus slave devices are manufactured by various companies ranging from flow computers to ‘smart’ transducers to power meters, displays, controllers, and much more… all of which can now be interrogated by the IntelliLogger IL-Mini™ with the new Modbus Master option.

IntelliLogger IL-Mini’s™ equipped with the Modbus RTU Master option can read (and optionally write) register values from (to) other Modbus networked Slave devices. 1000’s of Modbus slave devices are manufactured by various companies ranging from flow computers to ‘smart’ transducers to power meters, displays, controllers, and much more… all of which can now be interrogated by the IntelliLogger IL-Mini™ with the new Modbus Master option.

Programming the IntelliLogger IL-Mini™ as a Modbus RTU Master

Modbus RTU Slave Device Icon

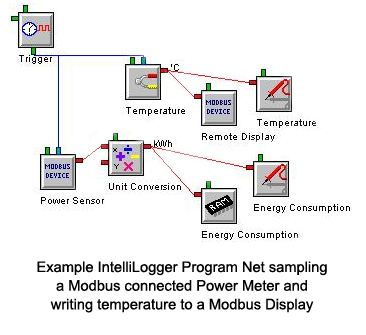

In the Modbus RTU Master mode, the IntelliLogger IL-Mini™ is programmed using the powerful and intuitive icon-based programming capability provided by HyperWare-II . A Program Net is built which can query the connected Modbus Slave device internal registers through the addition of an icon representing that register… much like the method used for logging conventional hardwired input and output sign.

A Modbus RTU Slave Device icon is added for each of the Slave device registers that the IntelliLogger IL-Mini™ will access. The values retrieved from the Slave device can then be used in further processing within the Program Net just like other analog or digital inputs that have been hardwired to the IntelliLogger IL-Mini™ (e.g. thermocouples, RTD’s, 4-20mA, voltages, etc). The values can be scaled, averaged, used in calculations, used in alarms and more.

Additionally, many Modbus Slave devices may have writable Registers… allowing the IntelliLogger IL-Mini™ to change settings within the Slave device by writing new values into these writable registers. Write functionality may be used for changing alarm thresholds, changing output states, adjusting operational constants, branching of algorithms, input scaling values within the device, etc.

Additionally, many Modbus Slave devices may have writable Registers… allowing the IntelliLogger IL-Mini™ to change settings within the Slave device by writing new values into these writable registers. Write functionality may be used for changing alarm thresholds, changing output states, adjusting operational constants, branching of algorithms, input scaling values within the device, etc.

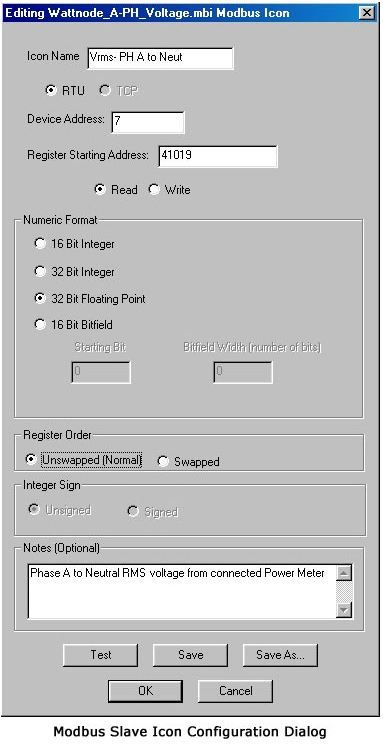

Modbus Slave icons are configured similarly to all HyperWare-II Program Net icons… through the Icon Configuration dialog. Within the Modbus Slave icon configuration dialog settings such as device address, Register address and data format are specified. The icon supports 16 and 32 bit integer, 32 bit floating point and even 16 bit ‘bitfield’ register types. Once the icon for a particular Slave device Register is made, it can be saved/opened from a growing library of Modbus icons for quick future use.

The IntelliLogger IL-Mini™ can now be ordered with the following Modbus support options:

Documentation

- Modbus Organization – http://modbus.org/

- Modbus Educational – https://en.wikipedia.org/wiki/Modbus

Frequently Asked Questions

- What is the difference between Modbus RTU and Modbus TCP?

- Simply put, the main difference is the means of transmission. Modbus RTU uses a serial communication link (typically RS-485 or RS-232) whereas Modbus TCP uses Ethernet for transmission.

- What Modbus protocols options are available for the IntelliLogger?

- Modbus RTU Master, Modbus RTU Slave and Modbus TCP Server.

- What Modbus protocols options are available for the IntelliLogger IL-Mini™?

- As the IL-Mini does not have Ethernet capability, only Modbus RTU Master and Modbus RTU Slave are available.