Modbus Option for the IL-Mini™ Overview

Modbus interface options for the IntelliLogger IL-Mini™

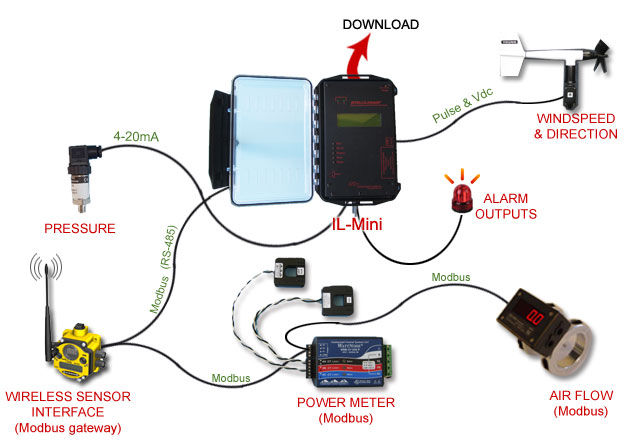

IntelliLogger IL-Mini™ shown with Modbus RTU connected Flow, Power and Wireless Sensor Modbus devices along with directly connected analog Temperature, Pressure and Wind direction and speed transducers

| Modbus Option Benefits | |

|---|---|

| Query connected Modbus ‘smart’ transducers | |

| Expose internal registers to other Modbus devices | |

| Remotely control IntelliLogger outputs | |

| Adjust IntelliLogger operation via Modbus | |

| Acknowledge IntelliLogger programmed alarms | |

| Change IntelliLogger alarm |

Product Information

Overview

IntelliLogger IL-Mini™ Modbus Capability

The IntelliLogger IL-Mini™ can be provided with Modbus RTU Master or RTU Slave capability as options.

A Modbus RTU Master enabled IntelliLogger IL-Mini™ can read Modbus register parameters from one or more connected Modbus Slave devices (e.g. a flow computer, transducer, etc) while simultaneously sampling conventional hardwired inputs (e.g. thermocouples, pressure transducers, etc). The Modbus values can then be processed, logged to memory and compared for alarms just like hardwired inputs.

Alternatively, the IntelliLogger IL-Mini™ can be configured as a Modbus RTU Slave and share its own internal Modbus registers with a Modbus Master device. Shared registers can be current analog or digital input values as well as calculated values and alarm states. Configuration is simply done via the Program Net developed from within HyperWare-II.

A Modbus educational overview as well as further details about the IntelliLogger Modbus feature are described below.

The IntelliLogger IL-Mini™ with Modbus opens up a whole new set of data collection, alarming and reporting capabilities. With the Modbus interface options, the IntelliLogger can be quickly programmed to perform functions such as:

- Query connected Modbus ‘smart’ transducers for Register values and utilize them in the IntelliLogger Program Net simultaneously with other hardwired inputs.

- Expose internal registers to other Modbus devices for use in their algorithms. Shared IntelliLogger Registers can be input, output and/or calculated values.

- Remotely control IntelliLogger outputs via Modbus communications from a Modbus Master

- Adjust IntelliLogger operation via Modbus communications during IntelliLogger program execution

- Acknowledge IntelliLogger programmed alarms

- Change IntelliLogger alarm thresholds during IntelliLogger program execution

The IntelliLogger IL-Mini™ can now be ordered with the following Modbus support options:

Documentation

- Modbus Organization – http://modbus.org/

- Modbus Educational – https://en.wikipedia.org/wiki/Modbus

Frequently Asked Questions

- What is the difference between Modbus RTU and Modbus TCP?

- Simply put, the main difference is the means of transmission. Modbus RTU uses a serial communication link (typically RS-485 or RS-232) whereas Modbus TCP uses Ethernet for transmission.

- What Modbus protocols options are available for the IntelliLogger?

- Modbus RTU Master, Modbus RTU Slave and Modbus TCP Server.

- What Modbus protocols options are available for the IntelliLogger IL-Mini™?

- As the IL-Mini does not have Ethernet capability, only Modbus RTU Master and Modbus RTU Slave are available.

Ordering

Modbus Protocol Background

Modbus Overview

Modbus is a serial communication protocol developed by Modicon originally for communication in their line of programmable Logic Controllers. The protocol was published and released for royalty free industry use as a standard communication path between two or more instruments, transducers and controllers and over the years has become a de facto industry standard. Modbus is now the most commonly used protocol for communications between a large offering of industrial instrumentation ranging from ‘smart’ transducers to data acquisition systems to control systems… hence the initiative to incorporate Modbus option into the Logic Beach IntelliLogger™data logging, reporting and alarming instrument family.

Modbus communication is quite simple in basic concept, a feature which led to its early and widespread adoptance by industry.

Modbus Master and Slave Concept

Modbus communication can be implemented as a communications scheme between two or more devices making up a network. In a Modbus network, communications will be between a Master and a Slave device (different terms are used for Modbus TCP but that will be explained later). Using special commands, the Master device interrogates the Slave device over the network periodically for information.

An example of a simple Modbus network is an IntelliLogger (being the Master) and a Modbus enabled pressure transducer being the Slave device. In normal operation, the IntelliLogger will interrogate the transducer periodically for its current pressure reading. The IntelliLogger will then use this pressure information as necessary… for example, logging it to local memory, turning on an alarm output, embedding into a Web page, etc.

Additionally, in many applications, the Master device can write to the Slave device, changing its internal settings and operation. For example, the pressure transducer above may have a local alarm output feature. The IntelliLogger could then read the pressure from the pressure transducer and if an alarm condition is detected, the transducer alarm could be turned on by the IntelliLogger by writing an alarm control value to the transducer.

Modbus Registers Concept

Modbus devices contain internal memory locations referred to as ‘registers’. The values stored in these Registers may be updated by the device itself in normal operation. In the pressure transducer example, the pressure transducer is periodically sampling the media pressure. The last sensed pressure value is stored in the ‘Last Pressure’ register. The IntelliLogger can then read this ‘Last Pressure’ register over the Modbus network and retrieve the last pressure read by the pressure transducer.

The alarm output feature in the pressure transducer mentioned above would also have a register associated with it. The IntelliLogger could control the alarm output in the pressure transducer by writing to the Alarm Output register with a On or Off command (e.g. a 1 or a 0).

In reality, Modbus devices normally have registers that are Read Only and Read/Write capable. In the pressure transducer mentioned above, there might be 10 or more Modbus registers containing calibration constants, temperature compensation values, sampling rate settings, last temperature, last pressure, averaged pressures, etc. More complex Modbus devices may have hundreds of registers.

Modbus Device Address Concept

As multiple devices can be connected in a Modbus network, each device is assigned a unique Modbus address. In this way, communications between devices can be directed to specific devices and other devices on the network can ignore the messages. Special ‘broadcast’ type commands do exist whereby a message is broadcast to all devices on the network for action.

Modbus Communication Serial Links

Most Modbus device networks are implemented with communication via a 2 or 4-wire RS-485 serial link. Some devices have Modbus implemented on an RS-232 link however RS-232 does not readily allow for more than two devices to be interconnected.

More recently, Modbus has been implemented over Ethernet allowing for multiple devices in a network using ubiquitous Ethernet network components (routers, switches, cellular, etc) that make up LAN’s and even over the Internet. Modbus over Ethernet is referred to as Modbus TCP/IP.

Modbus RTU and Modbus ASCII

Excluding Modbus TCP/IP, two variants of Modbus exist that are used in non-TCP/IP networks, Modbus RTU and Modbus ASCII. The difference between these protocols is the format used in the commands. Modbus RTU uses binary characters and Modbus ASCII uses ASCII characters. Modbus RTU is most common and is supported by the IntelliLogger in both the Modbus RTU Master and Modbus RTU Slave options.

Modbus TCP/IP

Modbus TCP/IP (commonly referred to as Modbus TCP) uses the same Modbus commands, however the commands are encapsulated within TCP/IP packets to allow them to move on LAN’s and over the Internet.

Rather than Master and Slave terminology, communicating devices on a Modbus TCP/IP network are referred to as Server and Client. In the above example… the IntelliLogger would be the Client device and the pressure transducer would be the Server (it ‘serves’ its pressure values to the Client). The IntelliLogger Modbus TCP option supports use of the IntelliLogger as a Modbus Server… allowing other network Client devices to garner register values from the IntelliLogger.