Compressed Air Audit Data Collection with the IL-Mini™

Example Audit Programs

Using the IL-Mini for Compressed Air Audits

The new low-cost, IL-Mini can meet your smaller Compressed Air Audit instrumentation needs perfectly! The IL-Mini is well-suited to audit applications with these requirements…

The new low-cost, IL-Mini can meet your smaller Compressed Air Audit instrumentation needs perfectly! The IL-Mini is well-suited to audit applications with these requirements…

- For audits on one or two compressors at a time (limited channel count)

- Do NOT need remote communication to the instrument

- Require stand-alone, self-contained, battery or grid powered operation

- Require flow and/or pressure profiling at various remote points on the air distribution manifold to augment compressor location data collection.

The IL-Mini is a flexible, low-cost data acquisition instrument for compressed air audit applications requiring a lower total count of transducer inputs and with no requirements for LAN connection or remote communication(eg via Cell Modem) access. With its optional internal battery pack and transducer excitation power supply (PSM-4) it is well suited for deployment at a compressor site where it will perform autonomous data collection for days to months. Using its four analog inputs, the IL-Mini is well suited for audits at sites with one or two compressors. If the Modbus interface is used, up to 16 Modbus transducers can be connected in addition to the four analog inputs allowing for simultaneous audits of multiple compressors. Additionally, the IL-Mini is perfect for pairing with a flow and/or pressure transducer and deploying at remote locations on the air distribution manifold for characterizing demand side performance.

Fully programmable via HyperWare-II, the IL-Mini is readily programmed to sample inputs at a user defined rate, process the signals then store to internal or optional CF card memory based on a method defined by the user. The data storage method can include simple time-based storage or more intelligent logging strategies based on changes in inputs, rate of changes, compressor state, other channel status or any of a multitude of simply programmed data storage schemes. Ultimately the IL-Mini coupled with HyperWare-II has the intelligence and flexibility to log data in a manner that reduces the auditor’s post-processing and data reduction effort… without loss of meaningful data.

IL-Mini™ Features make for Easier Compressed Air Audits

The IL-Mini possesses a multitude of powerful features and flexibility to assist auditors in implementing efficient and thorough compressed air audits…

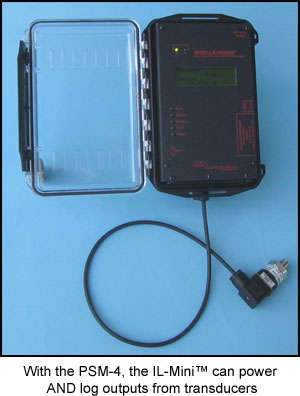

Rugged Weatherproof Packaging

Pre-packaged in a weatherproof plastic enclosure… the IL-Mini is well-suited for deployment in the demanding environments commonly encountered in industrial compressor rooms. Through the clear front cover, current signal inputs, calculated values and status can all be observed on the optional multi-line display during setup and real-time during the compressed air audit.

HyperWare-II Programmability

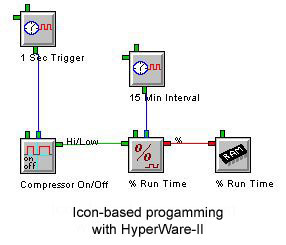

The IL-Mini uses HyperWare-II, icon-based programming software to provide unlimited programmability with a simple and intuitive visual interface. Simply interconnecting icons with your mouse builds a program which is then uploaded into the IL-Mini™ memory where it executes.

Although simple to program, the IL-Mini™ is unlimited in its ability to perform powerful data collection schemes… lessening the need for tedious, post-data collection data manipulation.

In addition to intelligent logging of typical Compressed Air Audit analog inputs, the IL-Mini™ is easily programmed through HyperWare-II to log calculated data as well such as differential pressure across a dryer or filter.

Example Compressed Air Audit Program Nets

For quick reference and to demonstrate the capability of the IL-Mini™, here are a couple of real-world Compressed Air Audit data logging strategies that can be quickly implemented with HyperWare-II and the IL-Mini™…

Flexible Analog Inputs

The IL-Mini™ includes four user programmable analog inputs. These inputs can be field configured for direct connection of all of the standard industrial signal and transducer outputs including direct connection of seven thermocouple types, dc current ranges (including the 4-20mA loop range) and dc Voltage ranges. With this complement of inputs, power, pressure, temperature and air flow transducers commonly used in Compressed Air Audits can all be quickly connected. See the IL-Mini™ Specifications for full channel details.

Digital Input

A field configurable digital input is provided on all IL-Mini™ models. The input can be user configured for Event, high-speed count or frequency inputs making it perfect for triggering logging based on compressor startup, totalizing power from pulse output energy meters or air flow meters.

Modbus Interface

The IL-Mini™ has an optional Modbus RTU interface. Configured as a Modbus RTU Master, the IL-Mini™ can garner readings from intelligent Modbus RTU Slave transducers such as power meters, flow meters, compressor controllers and 1000’s of other Modbus RTU enabled devices. Up to 32 devices can be daisy chain linked to a single IL-Mini™. In compressor rooms with multiple compressors, this allows for installation of flow meters, power meters and even Modbus enabled pressure transmitters on each compressor and simultaneous logging of the contributions of each. Modbus Details

PSM-4 Transducer Excitation Power Supply

With the PSM-4 option, the IL-Mini™ can provide 10, 15 or 24Vdc output to power transducers as well as 4-20mA transmitter loops from the internal batteries! With 100mA drive capability, sufficient current can be provided to power a loop for each of the IL-Mini™ four analog inputs. The PSM-4 solves the installation headache we have all encountered when looking for transmitter loop power at a site. Via HyperWare-II, the PSM-4 can be cycled ON prior to a reading then OFF after the reading, conserving IL-Mini™ battery life.

An IL-Mini™ equipped with the PSM-4 option and a pressure transducer results in a powerful Demand Side air manifold data collection instrument. Deploy multiple time synchronized IL-Mini™ satellite systems on manifold branches throughout the facility to characterize distribution piping losses, load induced pressure drops and other problems. At the end of the data collection phase, download the data and combine with compressor supply side data for a full Compressed Air system profile.

Grid or Battery Power

If grid power is available, use the 12Vdc or 24Vdc wall adapter to power the IL-Mini™ (and PSM-4 if so equipped). Internal batteries providing up to a couple months of autonomous data logging are provided as an option. In the event of a power failure, the IL-Mini™ automatically falls back to its internal batteries and continues operation.

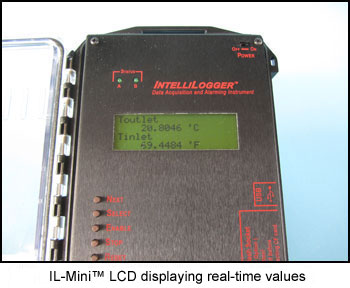

Integral Display

With the optional LCD display, read real-time measured and calculated values as well as system status… from battery state of charge to remaining memory, custom messages, and more. The LCD can be configured for manual (user initiated) sequencing of real-time readings or for automatic sequencing. With automatic sequencing, the IL-Mini™ front cover can be closed and secured and staff can view a sequencing display of readings and messages through the IL-Mini™ clear front cover.

Transducers Commonly Deployed for Compressed Air Audits

Logic Beach distributes a variety of transducers commonly used in the Compressed Air Audit process. These transducers are manufactured by reputable partner companies and have been industry proven to dovetail perfectly with the IntelliLogger and IL-Mini™ ultimately providing confidence to our customers that the total data acquisition platform will meet and exceed their Compressed Air Audit needs.

A few of the commonly bundled Compressed Air Audit appropriate transducers follow…

Compressor Power and Energy

A full spectrum of power and energy transducers are offered ranging from simple clamp-on CT’s for single phase measurement and calculated power/energy to high accuracy 3-phase power and energy measurement devices.

Pressure is a core parameter required for characterizing Compressed Air system Supply and Demand side dynamics. Two pressure transducer models commonly deployed for compressed air audits are:

Pressure is a core parameter required for characterizing Compressed Air system Supply and Demand side dynamics. Two pressure transducer models commonly deployed for compressed air audits are: